With the global focus on renewable energy and efficient agricultural utilization, grass pellet production has become an increasingly attractive investment. Grass-based pellets are widely used in animal feed and biomass fuel applications, offering improved storage, transportation, and usability. At the core of this process is the grass pellet machine, which enables producers to convert loose grass materials into high-density, uniform pellets suitable for commercial use.

What Are Grass Pellets and Why Are They Valuable?

Grass pellets are produced from various forage and pasture materials, including alfalfa, ryegrass, elephant grass, pasture grass, and mixed hay residues. These raw materials are widely available in agricultural regions but are often underutilized or discarded due to storage and transportation challenges.

By pelletizing grass, producers significantly increase its bulk density while reducing moisture and dust. This transformation improves handling efficiency and allows grass-based materials to enter higher-value markets such as commercial feed supply chains and renewable biomass energy systems.

(Related Post: https://biomasspelletizer.com/grass-pellet-machine/)

How a Grass Pellet Machine Works

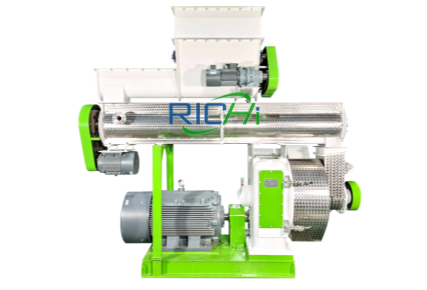

A grass pellet machine is specifically designed to handle fibrous, lightweight raw materials. Before pelletizing, grass is typically crushed into a uniform size to ensure smooth feeding into the pellet mill. Under high pressure and temperature, the material is compressed through a die, forming cylindrical pellets with consistent diameter and length.

Compared with raw grass or hay bales, pellets offer:

- Higher energy or nutrient concentration

- Reduced storage space requirements

- Improved feeding or combustion efficiency

These advantages make pelletizing an essential step for modern grass processing projects.

Industrial Grass Pellet Production Line Solution Overview

For commercial-scale projects, a single pellet machine is often insufficient. Many producers adopt a complete industrial grass pellet production line solution to ensure stable output and consistent pellet quality.

Typical Production Line Configuration

A standard grass pellet production line usually includes:

- Grass crushing system

- Drying system for moisture control

- Pelletizing section

- Cooling and screening units

- Automatic packing system

Each stage plays a critical role in ensuring pellet durability, moisture balance, and final appearance. Integrated systems also allow better automation and reduced labor costs.

Adaptability to Different Grass Materials

One of the key strengths of modern grass pellet production lines is their adaptability. Fresh grass with high moisture content can be dried before pelletizing, while pre-dried hay or forage residues may enter the process directly after crushing.

This flexibility allows producers to:

- Adjust to seasonal raw material changes

- Process mixed grass formulations

- Maintain continuous production throughout the year

Such adaptability is especially valuable for agricultural regions with variable climate conditions.

Operating Efficiency and Cost Considerations

Energy consumption, wear resistance, and maintenance cost are major concerns when selecting pelletizing equipment. High-quality grass pellet machines are built with reinforced dies, optimized roller structures, and stable transmission systems to handle fibrous materials efficiently.

Before purchasing equipment, investors are encouraged to review technical specifications and real project cases. You may click reference to explore practical grass pellet production examples and understand how different system configurations perform under real operating conditions.

Grass Pellets for Animal Feed Applications

In the feed industry, grass pellets are commonly used for cattle, sheep, horses, and other ruminants. Pelletized grass offers uniform nutrient distribution, reduced feed waste, and improved palatability. It also minimizes dust, which benefits both animal health and farm working conditions.

In some regions, grass pellets are blended with straw, grain by-products, or protein additives to create balanced feed formulas. This versatility further expands their market potential.

Grass Pellets as Biomass Fuel

Beyond feed applications, grass pellets are increasingly used as biomass fuel. Their consistent size and low moisture content make them suitable for boilers, heating systems, and small-scale power generation. Compared with loose grass, pellets burn more evenly and support automated feeding systems.

As governments continue to promote renewable energy policies, grass-based biomass pellets are expected to see sustained demand growth worldwide.

Choosing a Reliable Equipment Manufacturer

Selecting the right equipment supplier is essential for long-term project success. Manufacturing experience, engineering support, and system integration capability all influence production stability. Richi Manufacture has extensive experience in pelletizing equipment and biomass processing solutions, offering machinery suitable for a wide range of grass pellet applications.

Experienced manufacturers can assist with equipment selection, line layout planning, and operational guidance, helping investors reduce risks during the initial setup phase.

Conclusion: A Practical Path to Grass Resource Utilization

Grass pellet production offers a sustainable and economically viable way to utilize abundant grass resources. Whether for animal feed or renewable energy, pelletizing transforms low-density raw grass into standardized, market-ready products.

By investing in a reliable grass pellet machine and a well-designed industrial grass pellet production line solution, producers can achieve stable output, improved efficiency, and long-term value in an increasingly competitive market.